A shrink-proofing technique for making wool garments machine washable has been developed, which is less complex and costly than traditional shrink proofing processes whilst also reducing water, chemical and energy consumption.

Energy efficient

Uses less water, energy and chemicals than traditional machine-washable treatments.

Less complex

Can use treatment on garment and also suited to lambswool knitwear.

More accessible

Modern adaption of ozone treatment.

The development nearly 50 years ago of machine washable wool, sometimes known as superwash wool, revolutionised the wool industry and it has been extensively adopted. It means that consumers are able to easily launder a wide range of wool garments in their domestic washing machine without fear of the product shrinking, losing its shape or felting.

However, as part of its commitment to minimise wool’s environmental footprint along the supply chain, The Woolmark Company has worked with Spanish-based machine manufacturer Jeanologia to commercialise a new, more eco-friendly process to make wool garments machine washable.

WoolUp uses significantly less chemicals, water and energy than the traditional method and its impact on the environment is very small. The treatment doesn’t compromise the laundering performance of the garment. The process is also much less complex and more accessible than the traditional process. It is suitable for use on an industrial scale.

It has been proven that significant savings can be made when dyeing after the WoolUp treatment with reactive dyes, particularly for mid-to-light shade depths. Treating of pre-dyed garments shows almost no noticeable colour change.

How it works

WoolUp

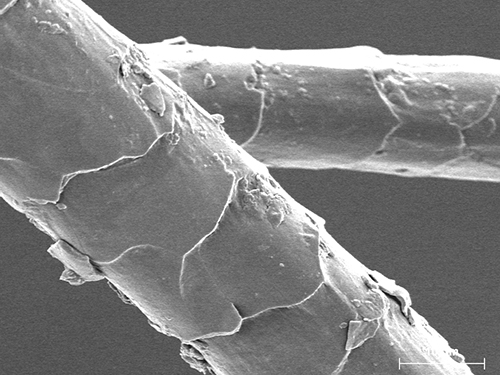

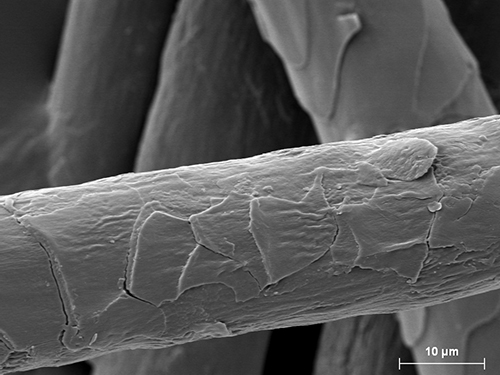

The WoolUp treatment is a relatively simple dry process that treats product in garment state using an ozone treatment that modifies the surface of the wool fibres. It removes the tips of the scales and smooths the fibres which allows them to slide against each other without interlocking, thereby preventing felting and shrinking.

While ozone has been known for many years to work in the modification of the surface of wool fibre, Jeanologia’s WoolUp process is an excellent modern adaptation and adoption of existing science.

The WoolUp process can be used for the treatment of worsted and woollen apparel (100% wool and wool blend). However, the technology is a breakthrough particularly for companies wishing to enter the lambswool knitwear market, in which machine washable claims have previously been difficult to achieve due to the nature of the finishing required and its complexity.